The Ultimate Guide to the Egg Deleup Process: Revolutionizing Egg Preservation

Introduction to the Egg Deleup Process

The Egg Deleup Process is a groundbreaking approach to egg preservation that optimizes quality, enhances safety, and extends shelf life. Unlike traditional methods, this process incorporates advanced cleaning, coating, and storage techniques to ensure that eggs remain fresh for longer periods without compromising their nutritional value. It addresses common challenges in the poultry industry, offering solutions that benefit both producers and consumers.

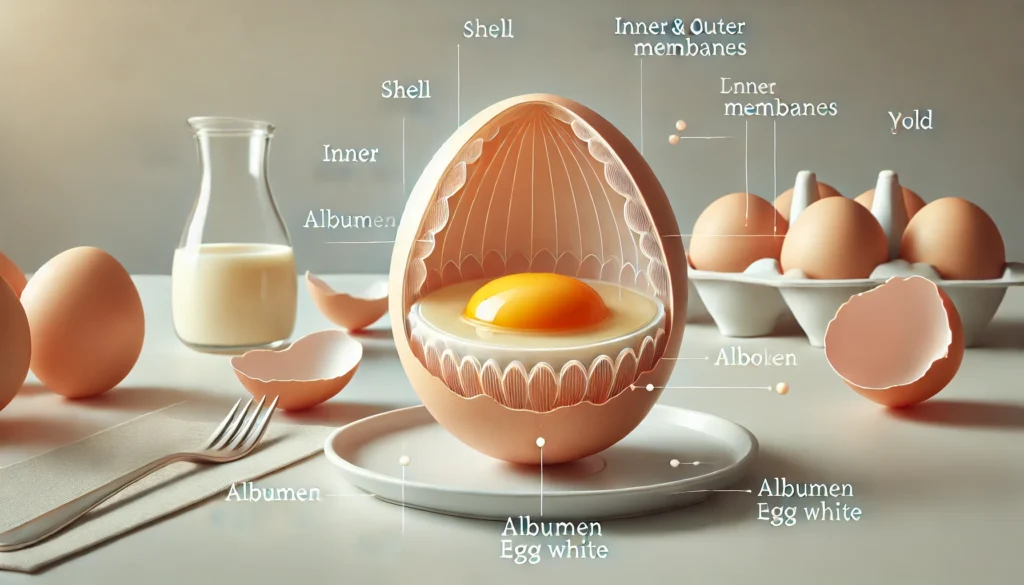

Understanding the Anatomy and Composition of an Egg

To appreciate the Egg Deleup Process, it’s important to understand the structure of an egg. An egg consists of four main parts:

- Shell: A calcium-rich outer layer that protects the egg from physical damage and microbial contamination.

- Inner and Outer Membranes: These layers beneath the shell act as additional barriers against bacteria.

- Albumen (Egg White): A protein-rich component that provides water and cushioning for the yolk.

- Yolk: The nutrient-dense core, rich in fats, proteins, and vitamins.

The integrity of these components is crucial for preserving egg quality, which is why the Egg Deleup Process focuses on protecting them.

Traditional Methods of Egg Preservation

Over the years, various methods have been used to prolong the freshness of eggs. These include:

- Refrigeration: While refrigeration slows microbial growth, it can also cause moisture loss over time.

- Water Glassing: Submerging eggs in a solution of water and lime seals the shell, preserving freshness for up to 12 months.

- Oil Coating: Applying a layer of mineral or vegetable oil to the shell blocks air and contaminants.

- Pickling and Freezing: These methods alter the egg’s state to ensure long-term usability but significantly change the taste and texture.

While effective to some degree, these methods often fall short of meeting modern consumer and industry demands, paving the way for the Egg Deleup Process.

The Egg Deleup Process: A Revolutionary Approach

Step 1: Cleaning and Sterilization

The first step in the Egg Deleup Process involves thoroughly cleaning the eggs to remove dirt and bacteria. This step uses food-safe solutions and advanced cleaning equipment to ensure the shell is free of contaminants.

Step 2: Coating the Eggshell

A protective coating is applied to the eggshell. This can include edible wax or specialized oils that seal the shell, minimizing moisture loss and preventing bacterial contamination.

Step 3: Moisture Retention Techniques

To maintain the egg’s freshness, moisture retention treatments are applied. These ensure that the albumen and yolk remain hydrated, preserving the egg’s texture and nutritional profile.

Step 4: Temperature Optimization

The eggs are stored in temperature-controlled environments. This prevents thermal stress, which can compromise quality, and ensures consistent freshness.

Step 5: Rigorous Quality Checks

Finally, eggs undergo a stringent quality inspection process. Those that meet the highest standards are approved for sale, while others are repurposed or discarded.

Benefits of the Egg Deleup Process

The Egg Deleup Process offers numerous advantages:

| Benefit | Description |

|---|---|

| Extended Shelf Life | Preserves eggs for weeks or even months longer than traditional methods. |

| Improved Safety | Reduces the risk of contamination, ensuring safer eggs for consumption. |

| Nutritional Preservation | Maintains the egg’s protein, vitamin, and mineral content. |

| Sustainability | Reduces food waste by minimizing spoilage and enhancing global transportability. |

Implementing the Egg Deleup Process in Poultry Farms

The Egg Deleup Process is scalable and adaptable for farms of all sizes. Large-scale producers can invest in automated systems, while smaller operations can use simpler versions of the same techniques. Training workers and maintaining equipment are key steps in successful implementation.

Conclusion

The Egg Deleup Process is a transformative innovation in egg preservation. By combining advanced techniques with traditional practices, it addresses key challenges in the poultry industry. It not only extends shelf life but also ensures better safety and quality for consumers. This comprehensive guide highlights the potential of this revolutionary method to reshape egg production for the better.

FAQs About the Egg Deleup Process

Is the Egg Deleup Process safe for consumers?

Yes, all steps are designed to meet food safety standards.

Can the Egg Deleup Process be applied to different types of eggs?

It works for chicken, duck, and quail eggs, making it versatile.

How does it differ from oil coating?

The process involves multiple steps beyond coating, including sterilization and moisture retention.

Does it increase the cost of eggs?

While initial costs may rise, reduced spoilage offsets this expense in the long term.

Can I identify eggs processed using this method?

Some producers label their eggs with “Processed using Egg Deleup Technology.”

Can the Egg Deleup Process help reduce transportation damage?

Yes, the process strengthens the eggshell’s integrity by applying protective coatings, making eggs more resistant to cracks and breaks during transportation. This ensures that eggs arrive in better condition, especially over long distances.

How does the Egg Deleup Process impact the taste of eggs?

The process does not alter the natural flavor or texture of eggs. Instead, it preserves their freshness, ensuring a better taste by maintaining the quality of the albumen and yolk for extended periods.

Is the Egg Deleup Process environmentally friendly?

Yes, the process reduces food waste by extending egg shelf life, which in turn minimizes the environmental impact of discarded spoiled eggs. Additionally, the coatings used are often biodegradable and food-safe.

Can this process make eggs safer for raw consumption?

While the Egg Deleup Process significantly reduces contamination risks, consuming raw eggs still carries some level of risk. It is advisable to use pasteurized eggs for recipes that require raw eggs.

Are there specific storage conditions required for eggs treated with this process?

Eggs processed using the Egg Deleup Process should still be stored in cool and dry conditions. However, they are more resistant to spoilage under less-than-ideal conditions compared to traditionally preserved eggs.

Recommended Articles:

Allintitle:When Does Amazon Stop Accepting Venmo? Detailed Guide on Payment Changes

Barbara Blake Schuldenfrei Queens NYC – Legacy of Community Leadership

The Ultimate Guide to Poser V4 Z Tresomme: Features, Benefits, and Expert Tips

Tulane Baha’i Club: A Comprehensive Guide to Unity, Service, and Spiritual Growth

The Ultimate Guide to the Egg Deleup Process: Revolutionizing Egg Preservation