Comprehensive Guide to -bearing_shield_petg_v9.2_small_big: Features, Printing, and Maintenance

Introduction

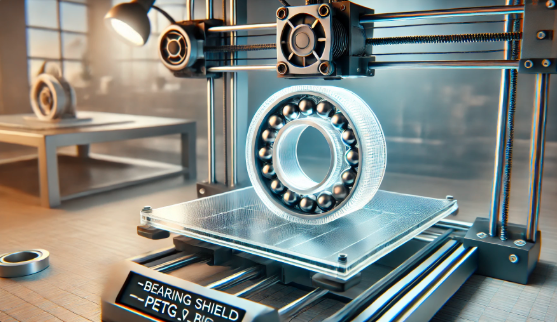

The “-bearing_shield_petg_v9.2_small_big” is an innovative 3D-printed solution designed to protect the bearings in 3D printers from dust, dirt, and other contaminants. Bearings play a critical role in ensuring smooth movement of printer components, and their maintenance can be a challenge if not adequately shielded. This guide explores everything you need to know about this component, including its unique features, benefits, and usage instructions.

Understanding Bearing Shields

Bearing shields act as protective covers that safeguard bearings from exposure to external contaminants. In a 3D printing environment, bearings often encounter particles that can accumulate and impair their functionality. Over time, these particles increase friction and lead to mechanical wear and tear, reducing the efficiency of the printer. The “-bearing_shield_petg_v9.2_small_big” addresses this problem effectively, ensuring longer life and consistent performance of your bearings.

Why Choose PETG for -bearing_shield_petg_v9.2_small_big?

Polyethylene Terephthalate Glycol-modified (PETG) is the material of choice for the -bearing_shield_petg_v9.2_small_big. PETG is known for its combination of durability, flexibility, and ease of use in 3D printing. Here are some reasons PETG is ideal for this application:

- Durability: PETG offers high strength, ensuring the shield can withstand mechanical stresses during printer operation.

- Heat Resistance: The material performs well in the elevated temperatures typical of a 3D printer’s operating environment.

- Low Warping: Unlike other materials, PETG exhibits minimal warping during the printing process, ensuring a precise fit.

- Chemical Resistance: This property makes PETG resistant to various chemicals, adding to the shield’s longevity.

Version 9.2 Enhancements

The -bearing_shield_petg_v9.2_small_big has seen multiple improvements in its latest iteration. Version 9.2 introduces refinements that cater to the evolving needs of 3D printer users:

- Improved Fit: The design has been optimized to fit a wide range of 3D printer models snugly.

- Reinforced Design: Additional structural support enhances the shield’s durability.

- Size Variations: The shield is available in both small and big versions, accommodating different printer configurations.

Comparing Small and Big Sizes

| Feature | Small Version | Big Version |

|---|---|---|

| Dimensions | Compact, lightweight | Larger, more robust |

| Compatibility | Ideal for smaller printers | Suitable for larger printer models |

| Use Case | Tight spaces, precision-focused | High-volume, heavy-duty usage |

Both versions offer unique benefits, allowing users to select the one that best suits their specific printer model and operational needs.

Printing Guidelines

To ensure the best results when printing the -bearing_shield_petg_v9.2_small_big, follow these guidelines:

- Layer Height: Set the layer height to 0.2mm for a balance between detail and print time.

- Infill Density: Use an infill density of 30% for durability without excessive material usage.

- Print Speed: Maintain a print speed of 50mm/s for precision.

- Temperature Settings: Set the extruder temperature to 230°C and the bed temperature to 70°C.

- Adhesion: Apply a glue stick or use a PEI sheet to enhance bed adhesion and prevent warping.

Installation Instructions

Installing the -bearing_shield_petg_v9.2_small_big is straightforward. Here are the steps:

- Prepare the Tools: Ensure you have the necessary tools, such as a screwdriver and cleaning cloth.

- Remove the Old Shield: If applicable, carefully detach the existing shield.

- Clean the Area: Wipe the bearings and surrounding area to remove dust and debris.

- Attach the Shield: Align the -bearing_shield_petg_v9.2_small_big with the bearing and secure it in place using screws or clips as required.

Maintenance Tips

To prolong the lifespan of the -bearing_shield_petg_v9.2_small_big and the bearings it protects, follow these maintenance practices:

- Regular Cleaning: Remove the shield periodically to clean any accumulated debris.

- Lubrication: Apply a suitable lubricant to the bearings to reduce friction.

- Inspection: Check the shield and bearings for wear and replace them as needed.

Frequently Asked Questions (FAQs)

- What printer models are compatible with the -bearing_shield_petg_v9.2_small_big? The shield is designed to fit a variety of 3D printer models. Refer to the specifications for compatibility details.

- Can I modify the design? Yes, the STL file can be customized to suit specific requirements.

- What is the expected lifespan of the shield? With proper maintenance, the shield can last several years.

- Is PETG the only material option? While PETG is recommended, other materials like ABS can be used with adjustments to the design and printing settings.

Conclusion

The -bearing_shield_petg_v9.2_small_big is an essential component for 3D printer enthusiasts looking to enhance the performance and longevity of their machines. Its thoughtful design, material selection, and size options make it a versatile solution for various printer setups. By following the printing and maintenance guidelines provided, users can ensure optimal results and extend the lifespan of their equipment.

Related Articles

Pedistool: Comprehensive Guide to History, Design, and Importance

Exploring eBook Hunter: A Comprehensive Guide

The Ultimate Guide to Botox Schampoo Bestest Produkt Hexlong